Anti-Flutter Foam is a specialized material that combats vibrations and flutter in vehicle structures, enhancing stability, safety, and ride quality by minimizing noise, vibration, and harshness (NVH). Lightweight and robust, it's ideal for fuel-efficient designs and protects sensitive electronics. As a strategic replacement in auto repair services, it offers significant advantages over traditional materials, commonly used in roofs, doors, hoods, and trunk lids. Modern anti-flutter foams provide superior shock absorption, enhance fuel efficiency, simplify installation processes like those seen in Mercedes-Benz repairs, and find applications in various components including chassis and suspension systems.

Anti-flutter foam has emerged as a game-changer in vehicle manufacturing, offering enhanced structural integrity and improved ride quality. This innovative material is designed to prevent the flutter effect, a common issue in light-weight vehicles where components can oscillate or ‘flutter’ at certain frequencies. In this article, we explore where anti-flutter foam is revolutionizing vehicle structures, focusing on key areas of replacement, its benefits over traditional materials, and why it’s becoming an indispensable component for modern cars.

- Understanding Anti-Flutter Foam: Its Role and Benefits in Vehicle Structures

- Common Areas Where Anti-Flutter Foam Is Used for Replacement

- The Advantages of Modern Anti-Flutter Foams Over Traditional Materials

Understanding Anti-Flutter Foam: Its Role and Benefits in Vehicle Structures

Anti-Flutter Foam, as the name suggests, is a specialized material designed to combat the harmful effects of flutter and vibrations in vehicle structures. It plays a pivotal role in enhancing the overall stability and safety of automobiles. This innovative foam is not just a simple replacement for traditional materials; it offers numerous benefits that significantly improve the performance and longevity of vehicles.

In auto repair services, anti-flutter foam is strategically incorporated into various parts of car bodywork to minimize unwanted noise, vibration, and harshness (NVH). By effectively managing these issues, it contributes to a smoother ride and enhances the overall driving experience. Moreover, its lightweight yet robust nature makes it an ideal choice for modern vehicle designs where fuel efficiency and reduced weight are paramount concerns. This foam’s ability to dampen vibrations also proves beneficial in protecting sensitive electronic components from potential car damage repair.

Common Areas Where Anti-Flutter Foam Is Used for Replacement

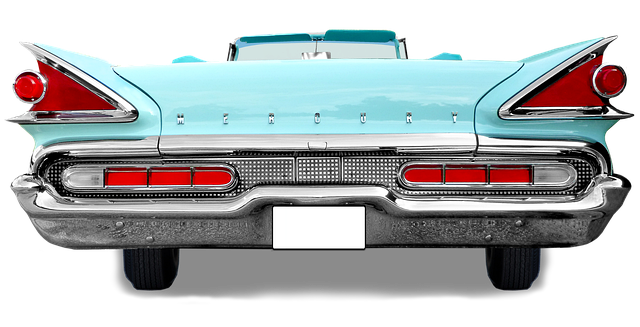

Anti-flutter foam is commonly used for replacement in various vehicle structures where vibrations and flutter can cause structural damage or compromise safety. These areas include the car’s roof, doors, hood, and trunk lids. In many cases, auto body services involve replacing old or damaged anti-flutter foam with new materials to ensure optimal performance and longevity of the vehicle. Car body restoration processes often require careful inspection to identify weak points where flutter issues might occur, allowing for targeted use of this specialized foam during repairs and refinishing, including auto body painting stages.

The Advantages of Modern Anti-Flutter Foams Over Traditional Materials

Modern anti-flutter foams offer significant advantages over traditional materials when it comes to vehicle structures. These advanced foams are designed to provide superior shock absorption and vibration isolation, ensuring a smoother ride for passengers and protecting sensitive components from damage. Unlike conventional materials, anti-flutter foams can be tailored to specific requirements, offering lightweight solutions without compromising structural integrity. This not only enhances fuel efficiency but also facilitates easier installation during vehicle manufacturing and repair processes, such as in Mercedes-Benz repairs.

Furthermore, the longevity of modern anti-flutter foams is a notable improvement. They are resistant to degradation from environmental factors like moisture and UV rays, which can often lead to the breakdown of traditional materials. This extended lifespan reduces the need for frequent replacements, making them a cost-effective choice for auto repair shops. In terms of applications, these innovative foams find use in various vehicle components, including chassis, suspension systems, and even in auto painting processes where precise vibration control is essential for achieving a perfect finish.

Anti-flutter foam has emerged as a game-changer in vehicle construction, offering lightweight yet robust solutions. Its strategic placement in various structural components enhances safety and performance, especially during high-speed manoeuvres. As modern foams continue to evolve, they provide an advantageous alternative to traditional materials, ensuring smoother rides and improved fuel efficiency. When considering anti-flutter foam replacement, its unique properties and benefits for vehicle structures are undeniable.